Warning: Undefined variable $post_link in /home/u811379278/domains/x-mold.com/public_html/wp-content/themes/hello-theme-child-master/template-parts/single.php on line 57

Accelerating Injection Mold Lead Time: Key Factors and Strategies

June 7, 2024

Injection mold lead time is important in determining the success and efficiency of injection molding projects. Manufacturers, engineers, and project managers must understand injection mold lead time. In this post, we will explore its significance in the injection molding process, examine the factors that affect it, and discuss strategies to optimize and reduce lead time for improved project outcomes.

What is Injection Mold Lead Time?

Injection mold lead time refers to the total duration from when a purchase order is placed for a mold until the finished mold is delivered and ready for production. The typical injection mold time is from 2-4 weeks to 1-6 months.

Injection Mold Lead Time Breakdown

The time required to produce an injection mold can vary significantly based on several factors. Here’s steps of how injection mold production time is constituted:

1. Design Phase (1-3 Weeks)

- Product Design: Finalizing the part design, ensuring it meets all specifications and is suitable for injection molding.

- Mold Design: Creating detailed designs for the mold itself, including considerations for cooling channels, ejection mechanisms, and parting lines.

2. Mold Fabrication (2-16 Weeks)

- Material Procurement (1-2 Weeks): Ordering and receiving the necessary materials for mold construction.

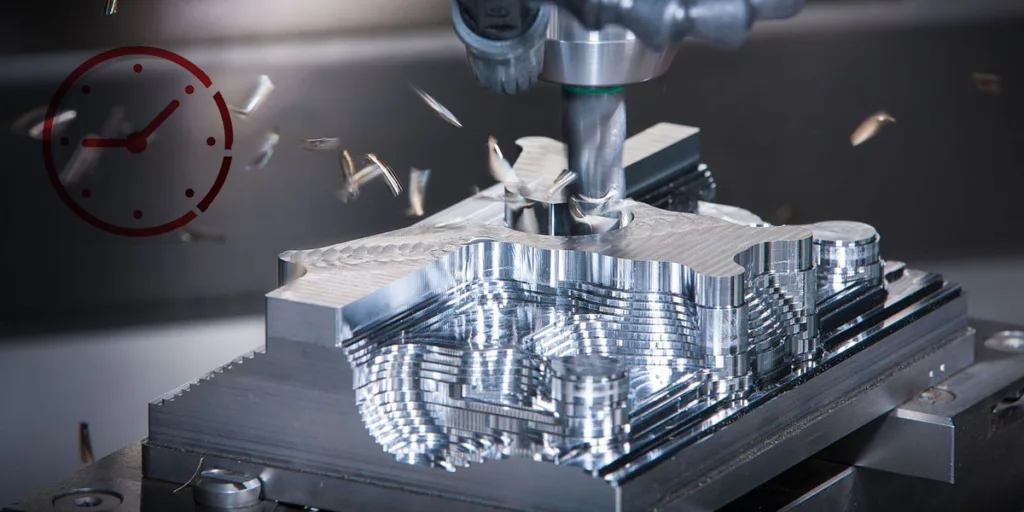

- Machining and Construction (2-12 Weeks): Actual construction of the mold using CNC machining, EDM (Electrical Discharge Machining), and other manufacturing techniques. Complex molds or those with multiple cavities take longer.

- Assembly and Fitting (1-2 Weeks): Assembling the mold components and ensuring they fit together correctly, making any necessary adjustments.

3. Testing and Validation (1-4 Weeks)

- Initial Testing (1-2 Weeks): Run the first test shots to check for defects, ensure the part dimensions are accurate, and verify the mold’s functionality.

- Corrections and Adjustments (1-2 Weeks): Making any necessary modifications to the mold based on initial testing results, which might include adjusting cooling channels, improving surface finish, or fixing any alignment issues.

4. Final Approval and Delivery (1-2 Weeks)

- Final Testing (1 Week): Conduct a final round of tests to ensure all adjustments have been successful and the mold produces parts to the required quality standards.

- Approval and Shipping (1 Week): Obtaining final approval from the client and shipping the mold to the production facility.

Factors Affecting Injection Mold Lead Time

- Mold Complexity: The design intricacies of the mold, including the number of cavities, the complexity of the part geometry, and the need for intricate details, can significantly affect lead time. More complex molds require more time for design, machining, and assembly.

- Material Selection: The type of material used for the mold (e.g., steel, aluminum) can impact the machining and manufacturing time. Different materials have varying hardness and machinability properties.

- Mold Size: Larger molds typically require more time to manufacture due to the increased amount of material and longer machining times needed.

- Tooling and Equipment Availability: The availability and capability of the tooling and equipment used in mold manufacturing can impact lead time. Advanced machinery and technology can expedite the process, while limited resources can cause delays.

- Design and Engineering Changes: Any changes in the design or engineering specifications during the mold-making process can extend lead times. Iterations and adjustments require additional time for redesign, approval, and re-machining.

- Manufacturing Process: The chosen manufacturing process (e.g., CNC machining, EDM, additive manufacturing) affects lead time. Some processes are faster but may have limitations in terms of precision or material compatibility.

- Materials Supplier Lead Time: The lead time provided by suppliers of materials, components, or outsourced services can affect the overall mold lead time. Delays in receiving these items can cause bottlenecks.

- Quality Control and Testing: Rigorous quality control, testing, and validation processes are essential to ensure the mold meets the required specifications. These steps, while crucial, add to the overall lead time.

- Project Management and Coordination: Effective project management and coordination among various teams (design, manufacturing, quality assurance) are critical. Poor communication or coordination can lead to delays.

- Customization and Special Features: Custom features, such as special surface finishes, texturing, or inserts, can add to the complexity and time required to produce the mold.

- Post-Processing Requirements: Additional processes after the initial mold creation, such as polishing, heat treatment, or coating, can extend the lead time.

Strategies to Reduce Injection Mold Lead Time

Reducing injection mold lead time can be crucial for accelerating product development and getting products to market faster. Here are several strategies that can help:

Streamline Design Processes:

Optimize the mold design for ease of manufacturing from the start. Simplify part geometry and minimize complex features. Use a concurrent engineering approach where design and manufacturing teams work simultaneously to reduce back-and-forth and identify issues early.

Use Modular Mold Design:

- Interchangeable Components: Design molds with interchangeable components to facilitate quick changes and modifications.

- Standard Mold Bases: Use standard mold bases and modular components to reduce custom manufacturing time.

Leverage Advanced Technologies:

- CNC Machining and EDM: Utilize high-speed CNC machining and EDM (Electrical Discharge Machining) for faster and more precise mold creation.

- Additive Manufacturing: Incorporate 3D printing for prototyping or even for creating mold components, which can significantly cut down lead time.

- Simulation Software: Use mold flow analysis and other simulation tools to predict and mitigate potential issues before actual manufacturing begins.

Optimize Material Use:

Avoid exotic or specialized materials unless absolutely necessary. Use pre-hardened steels to eliminate the need for heat treatment, which can save time.

Conclusion

Injection mold lead time is a crucial factor in the success of injection molding projects. It directly impacts project timelines, costs, and competitiveness in the market. To minimize lead time and maximize efficiency, manufacturers can implement key strategies such as streamlining the design process, leveraging advanced manufacturing technologies, simplifying mold design, etc. By adopting these strategies, manufacturers can accelerate time-to-market, improve production efficiency, and gain a competitive advantage in the injection molding industry.