Precision, versatility, and expertise

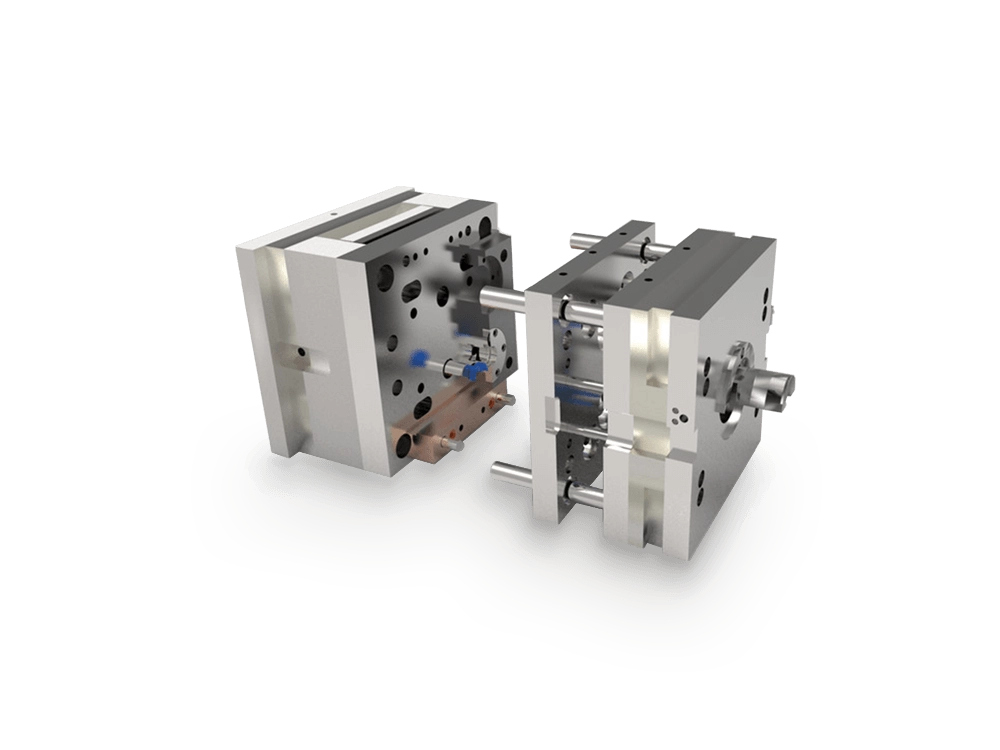

Collaborate closely with our skilled team to create a detailed 3D mold design using advanced CAD/CAM software.

Carefully choose the most suitable mold materials, such as steel or aluminum, ensuring durability and meeting production requirements.

Expert craftsmen use state-of-the-art CNC machines and precision tools to fabricate mold components with meticulous attention to detail.

Skilled technicians assemble and fit the mold components, making necessary adjustments to ensure optimal performance.

Rigorously test and evaluate each mold for functionality, part quality, and performance, making refinements as needed.

Meticulously finish and polish the mold surfaces to enhance durability and enable smooth ejection of molded parts.

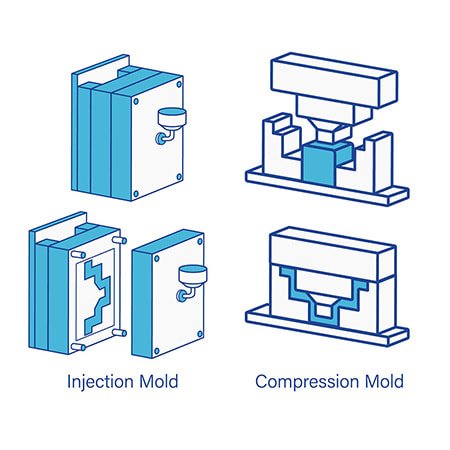

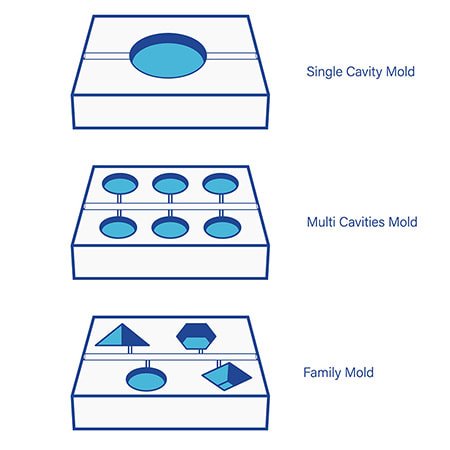

We offer superior mold manufacturing solutions to meet your specific requirements. Whether you require single cavity molds, multi-cavity molds, or family molds, or need injection molds or compression molds, we have the expertise to deliver exceptional

results.

Let us know your requirements, and our experienced team will work closely with you to provide tailored solutions that meet your needs.

Enjoy a wide arnge of customization options to meet your unique project requirements.

Benifit from our extensive knowledge and experience in the fielf of injection molding.

We offer competitive priing without compromising on quality or service.

Our team provides personalized support and guidance throughout the project.

Choose from a diverse range of high-quality materials for your injection molded parts.

Common inquiries about our mold service. Contact our service team if you have more questions.

The choice between steel and aluminum molds depends on factors like production volume, complexity of the part, and budget. Steel molds are more durable and suited for high-volume production, while aluminum molds are cost-effective for lower volumes and prototypes.

We utilize advanced CNC machining and precision tooling to ensure that the mold dimensions meet exact specifications. Rigorous quality checks and testing are performed throughout the manufacturing process to maintain accuracy.

We have a dedicated maintenance and repair team that conducts regular inspections and preventive maintenance to ensure molds remain in optimal condition. If any issues arise, we promptly address them to minimize downtime and maintain production quality.